Integrated BIM technology for design and construction of prefabricated U-grooves in railway subgrade

-

摘要:

为解决预制U型槽各构件设计深度不足、U型槽和泵站间接口复杂且易出现渗漏水病害、传统的预制构件外观质量检测手段效率低且精度不足的问题,开展铁路路基装配式U型槽设计施工一体化BIM技术研究。通过BIM深化设计,精细模拟钢筋、套筒、波纹管、下料孔等构件的空间位置关系,优化钢筋布置;进行泵站与U型槽主体结构一体化BIM设计,共用侧墙,消除二者连接薄弱点;制定预制U型槽外观质量检测标准,通过光学追踪激光扫描仪获取构件点云,开展关键尺寸分析处理,实现自动化外观质量检测。应用结果表明,该技术可有效降低钢筋干扰、增强设计整体性、提高外观质量检测的效率和精度,为铁路预制装配式结构提供了基于BIM的设计施工一体化解决方案。

Abstract:To solve the problems of insufficient design depth of prefabricated U-shaped groove components, complex interface between U-shaped groove and pump station, and low efficiency and accuracy of traditional prefabricated component appearance quality inspection methods, this paper researched on integrated BIM technology for the design and construction of prefabricated U-shaped grooves in railway subgrade. The paper conducted BIM deepening design, finely simulated the spatial position relationship of components such as rebar, sleeves, corrugated pipes, and feeding holes, and optimized the arrangement of steel bars; focused on the integrated BIM design of the pump station and U-shaped groove main structure, sharing side walls to eliminate weak connection points between the two; established a standard for the appearance quality inspection of prefabricated U-shaped grooves; obtained the component point cloud through an optical tracking laser scanner, and conducted the key dimension analysis and processing to implement automated appearance quality inspection. The application results show that this technology can effectively reduce rebar interference, enhance design integrity, improve the efficiency and accuracy of appearance quality inspection, and provide a BIM based integrated design and construction solution for railway prefabricated structures.

-

近年来,铁路用地管理的难度越来越大,管理的土地数量逐年递增,截至2023年,中国国家铁路集团有限公司(简称:国铁集团)铁路用地总面积约78万公顷(含合资和上市公司),人均管地面积由2015年的273公顷/人上升到2023年的885.48公顷/人[1],约为2015年的3.24倍,铁路用地管理工作面临越来越严峻的挑战;同时,管理的标准越来越严格,国务院办公厅和国铁集团相继颁布了《关于支持铁路建设实施土地综合开发的意见》(国办发〔2014〕37号)[2]、《铁路用地管理办法》(铁经开〔2021〕99号)[3],明确了所属单位应按照房地匹配、账实相符等要求建立相关台账,加强铁路用地及房屋等不动产统计管理。

当前,在大数据技术广泛应用的背景下,地理空间领域的数据融合技术成为研究的热门选题。龚国辉等人[4]从分类标准的视角出发,对国土资源数据融合性进行了初步探索与验证;马京振等人[5]开展了多尺度矢量空间数据融合的基本问题研究,通过大量实例统计分析多尺度矢量空间数据的差异性根源和表现形式,同时对多尺度融合的定义、分类、研究内容及技术框架等进行深入探讨;邹丹等人[6]提出一种铁路数据多源融合架构,将来自不同单位、不同部门、不同专业段的原始数据进行规范化处理,形成统一数据格式、属性字段等结构化信息,建立不同层次数据融合输入及输出项,实现对多种数据融合算法的特点和适用性的对比分析;年秋慧[7]对矢量数据融合算法进行了深入的研究,通过Hausdorff距离进行几何空间匹配,采用语义匹配模型进行矢量数据的属性信息融合处理,实现同一铁路要素实体的不同属性字段融合,以及相同属性字段的内容融合。

综上所述,随着卫星遥感、地理信息系统(GIS,Geographic Information System)、大数据、云计算等技术的发展,为缓解国铁集团和各铁路局集团公司(简称:铁路局)面临的铁路用地管理效能和监管力量不足的矛盾,在充分调研相关研究成果的基础上,本文提出了基于空间数据融合算法的铁路用地管理系统[8],构建全国铁路(简称:全路)用地空间数据管理体系,实现了土地权属管理、资产处置、综合开发、建设用地及用地监察等功能。

1 铁路用地管理系统设计

铁路用地管理系统根据铁路用地相关标准及管理办法要求,基于全路用地空间融合数据库,为国铁集团用户提供全路用地经营管理、统计分析等功能,为铁路局不同层级用户提供权属管理、资产处置、综合开发等功能,满足铁路权属、监察、处置及开发利用等业务需求[9-10]。

1.1 系统架构设计

铁路用地管理系统部署在中国铁路主数据中心,充分利用国铁集团的铁路数据服务平台和铁路地理信息平台的服务和资源,在符合铁路用地管理标准和保障网络安全的前提下,设计该系统的架构,如图1所示。

1.1.1 云平台层

该层是铁路用地管理系统运行的基础,通过运用服务器虚拟化技术、共享存储、负载均衡及网络安全等技术,提供云计算、云网络、云安全和云存储等服务,维护该系统稳定运行,同时,提供容灾该备份服务,运用通用服务提高了系统的扩展性,以应对未来业务发展。

1.1.2 数据层

该层是铁路用地管理系统数据存储的资源池,包括关系型数据库、对象存储、分布式存储和空间数据库。为有效保障数据库稳定与安全,该系统采用分布式存储架构提升容灾能力;通过对象存储技术强化非结构化文档管理,并基于空间数据库实现铁路用地空间数据的专项存储与空间分析功能。

1.1.3 业务层

该层支撑铁路用地管理系统运行,主要分为运行维护(简称:运维)服务和运行服务这2个部分。运行服务主要包括基础服务、数据集成和应用集成等。基础服务提供日志追踪、微服务治理、模糊检索优化及动态报表生成能力;数据集成使用了数据校验、转换、数据存储分析技术等;应用集成基于消息队列、GIS等技术实现异构系统对接与空间服务支撑。运维服务包括集中运营管理、网络监控及应用监控等。

1.1.4 应用层

利用前后端分离、移动开发等技术将铁路用地管理系统功能在移动端和网页端呈现,方便用户使用。

1.1.5 用户层

用户按所属机构层级分为国铁集团、铁路局/专业运输公司/非运输企业、土地管理机构和站段等4级用户。

1.2 系统功能设计

通过对各级用户的需求分析,设计铁路用地管理系统功能架构如图2所示。

1.2.1 权属管理

实现土地和房屋台账信息的查看、查询、导出、审核、锁定及统计汇总功能,提供专业台账及基础台账的菜单,按土地分类面积、土地收入、人员情况方面汇总统计综合报表,可调阅车站、区间、独立地块、土地证对应地上建筑物台账信息,统计指定范围的房屋面积等信息,从而帮助管理人员掌握铁路用地和房屋匹配情况,以及各所属单位的铁路用地和房屋资产台账情况。

1.2.2 资产处置

指对建设项目、开发项目、线路外迁类的资产处置事项的进展进行登记和管理,备案登记出租出借类的事项,提供资产处置备案事项预审、审批功能,并能展示、查询审批事项状态,统计各单位已签订资产处置事项合同的相关情况。资产处置界面如图3所示。

1.2.3 综合开发项目管理

指对土地综合开发项目规划、年度计划进行管理,对综合开发项目相关土地证信息、项目名称、项目概况等相关信息进行综合管理,并对项目实施情况进行监管。按数量、金额对各铁路局综合开发项目、综合开发年度计划进行统计排名,可按全路、铁路局、金额范围、时间等条件查询综合开发项目信息,并可导出查询结果。通过综合开发对铁路土地房产资产进行专业化经营,提升铁路土地房产资产收益。

1.2.4 建设用地管理

实现铁路建设项目管理、建设用地占地管理、竣工验收用地管理、统计分析管理等功能,统计并展示各铁路局新建及验收建设项目数量、建设用地占用既有用地情况、红线内用地情况、红线外用地情况,实现竣工验收用地各阶段关键节点管理功能,通过具体阶段查看上报的检查内容准备情况、现场检查记录情况及各阶段验收资料。

1.2.5 用地监察

提供年度巡查计划、问题库、被占台账管理、监察证管理、统计分析等功能。可查询年度巡查计划及其执行情况;可记录、查询问题的来源、等级、处置状态;可查阅被占台账列表及详情信息。用地监察界面如图4所示。

1.2.6 综合指标分析

依据国铁集团资产处置等业务台账,分析土地属性、使用情况及收益等内容,监督土地开发利用重点专项进展。对发生侵占的重点地块进行标识,针对被占用土地和存在纠纷的土地,分析其原因和结果,为保护土地资源、解决土地侵占等问题提供数据支撑。铁路用地管理系统综合指标界面如图5所示。

1.2.7 专项分析

按全路、铁路局、行政区等层级展示土地概况信息,实现全国铁路用地界限数据的三维动态全景展示,对铁路用地数据按用地属性、分管权限分级管理,在地图上显示土地的用地红线、位置等地理信息,集成显示土地证载信息、被占信息、资产处置等信息,跟踪土地动态,并提供授权经营、可开发利用、被占用、权属纠纷专题分析功能。

1.2.8 空间数据管理

提供铁路用地电子地图汇交管理,入库检查、数据处理和地图服务发布等功能,建立铁路用地电子图空间数据管理体系,收集全路用地电子图数据,以铁路地理信息平台基础GIS数据服务为基础,基于GIS引擎叠加铁路用地专题数据图层,逐步推进铁路用地电子图空间数据库建设。

2 关键技术

2.1 空间坐标变换

本文收集了8个铁路局的既有铁路用地数据。研究发现,各铁路局用地文件命名规则各异,数据精度不一致,坐标不统一,分别采用了北京54坐标系、西安80坐标系及各地方坐标系。8个铁路局铁路用地数据情况如表1所示。

表 1 铁路用地数据情况铁路局 汇交宗地数 宗地面积/

公顷占本局国铁

用地比例房屋/栋 房屋面积/

万m2北京 11 240.6 7.8% 983 109.6 郑州 46 1048 5.8% 591 26.6 济南 126 1918.6 11% 377 43.0 上海 182 3680 12% 1036 20.9 南昌 2323 22442 93% 3498 146.9 广州 31 133.7 0.6% 169 26.7 兰州 713 18971.4 68.6% 612 23.3 乌鲁木齐 184 10893.7 32% 1524 122.8 为统一各铁路局用地数据的坐标系,须进行空间坐标变换。规范数据文件名,将车站和区间名称追加到原文件名中,将各类格式数据转换为SHP格式数据,并将车站和区间名称追加到SHP数据中,将数据按坐标类型进行分组,作为后续判断坐标和处理的依据;再将分组数据对应的坐标系采用布尔莎七参数变换法进行空间坐标转换,转换成2000国家大地坐标系。

布尔莎七参数变换法应用7个参数来表现2个坐标系之间的变换关系,包括3个平移参数

ΔX、ΔY、ΔZ ,3个旋转参数ωx、ωy、ωz ,以及一个尺度变化参数m ,转换公式为:[xαyαzα]=[ΔXΔYΔZ]+(1+m)[1−ωzωyωz1−ωx−ωyωx1][xbybzb] (1) 转换过程如下。

(1)收集公共点坐标:在2个不同坐标系下,获取同一地区的至少 3 个公共点的坐标对,这些公共点的坐标精度对于转换结果的准确性至关重要。

(2)将已知坐标转换为地心空间直角坐标。

(3)计算七参数:应用收集到的公共点坐标对,代入布尔莎七参数模型,利用最小二乘法等算法求解七参数。

(4)坐标转换:利用转换公式将需要转换的坐标从一个坐标系转换到另一个坐标系。

2.2 空间数据融合算法

空间数据融合是指将来自不同来源或不同类型的空间数据综合处理,以获得更准确、更完整的信息。经典的空间数据融合算法包括加权平均、卡尔曼滤波、聚类分析、尺度不变特征转换(SIFT,Scale Invariant Feature Transform)等[11]。本文将经过布尔莎七参数坐标变换的铁路用地数据通过空间查询与天地图中的属性进行比对,基于SIFT算法提取图像中的关键像点,再根据基准图影像数据进行精度和位置校准[12]。

SIFT算法采用高斯金字塔作为关键模型,即将原始图像不断降阶采样,获得众多不同大小的图像,由大到小,自底向上构成塔状模型。原始图像作为金字塔的第1层,每次降阶采样得到的新图像为金字塔的下一层。为了保持图像的连续性,在简单向下采样的基础上采用多尺度的高斯滤波。设高斯金字塔共包含

o 组图像,每组图像有s+3 层,则o=log2(min (2) m 和n 分别为原始图像的行数和列数。设位于金字塔底的第1组的第1层图像,其高斯滤波的尺度为\partial (o=1,s=1)=\partial (1)1 ,k 为同一阶相邻两层的尺度因子比例,则位于第1组的其他层图像的高斯滤波尺度分别为\partial (o=1,s=2)=\partial (1)2=k\partial (1)1 ;\partial (o = 1, s = 3) = \partial (1)3 = {k^2}\partial (1)1 ,以此类推。同理可得到位于其他组的各层图像的高斯滤波尺度。SIFT算法的步骤主要有:提取图像中的关键点,即特征明显且不会因为客观条件的改变而发生变化的点,例如铁路用地边界点、与周围大范围数据存在明显差异的点等,搜索所有尺度的图像进行提取,利用高斯微分函数来识别具有尺度不变特点的关键点;通过模拟高斯金字塔实现关键点的位置及尺度的确定,同时判断关键点的稳定性,基于图像梯度方向提取关键点处至少一个方向,之后对不同图像数据的处理都基于关键点确定的方向、尺度、三维坐标进行计算;将不同关键点的特征向量进行互相比较,提取之间的关联关系,建立铁路用地图的空间关系。

2.3 基于GIS的土(地)房(屋)联动技术

铁路用地管理办法要求土地和房屋进行一体化管理,土地信息及地上房屋台账信息必须匹配。结合房屋台账信息业务应用,基于GIS技术在地图上标识出宗地界线、界址点、设备设施、土地动态、土地专项等铁路用地空间数据,采用房屋在线位置标记的方式,为每宗土地生成唯一身份的二维码,土地范围与地图汇交单元相对应,实现土房关联及地图和土地属性联动,支持“以地找房,以房查地”,助力建设全路土地、房屋“一本账”,并可在线生成铁路局土地经济效益分析报告。通过土地与房屋信息关联、地图与信息结合,实现铁路用地日常工作全流程全要素管理,促进提升铁路用地管理效能。

3 系统应用

铁路用地管理系统已于2023年12月—2024年3月在国铁集团及北京、郑州、济南、上海、广州、南昌、兰州、乌鲁木齐等8个铁路局集团公司开展试点应用。通过空间数据融合,将录入的铁路用地图数据整合到空间数据库,统一直观展示铁路用地图,附带显示用地范围、权属资料等信息,同时可根据不同数据图层对土地管理各项工作职能全面进行展示。

该系统提升了用地数据分析能力,涵盖土地属性、收益动态等专项数据,为日常业务分析提供数据支撑;提升了监察管理效率,实现计划、巡查、问题处理闭环程管理,将土地巡查职责落实到管地单位,切实发挥站段巡查力量;改变了日常土地管理工作模式,由年度统一数据录入的旧模式逐步形成自动生成被占用土地、临时租借、资产处置、合资公司占用情况等4本专业土地管理台账。该系统与业务工作紧密结合,为土地管理工作提供有力支撑与高效变革。

4 结束语

基于空间数据融合算法的铁路用地管理系统顺应国铁集团铁路用地管理标准要求,实现了铁路用地空间数据要素的采集分析和高效利用,可为国铁集团、各铁路局提升业务生产效率、有效节省管理成本服务,促进铁路用地资产处置和综合开发,从而提升整体铁路用地管理水平及效能。

下一步将开展基于GIS的铁路用地和房屋相关数据采集、存储和分析等关键技术研究,通过铁路土房空间数据的叠加分析进行房地自动匹配,实现铁路地籍电子资料现场随时调用查询和红线内/外高精度定位判识,方便现场巡查人员查阅铁路用地界线,提高巡查人员工作效率,促进铁路用地更高效、更精细化的管理。

-

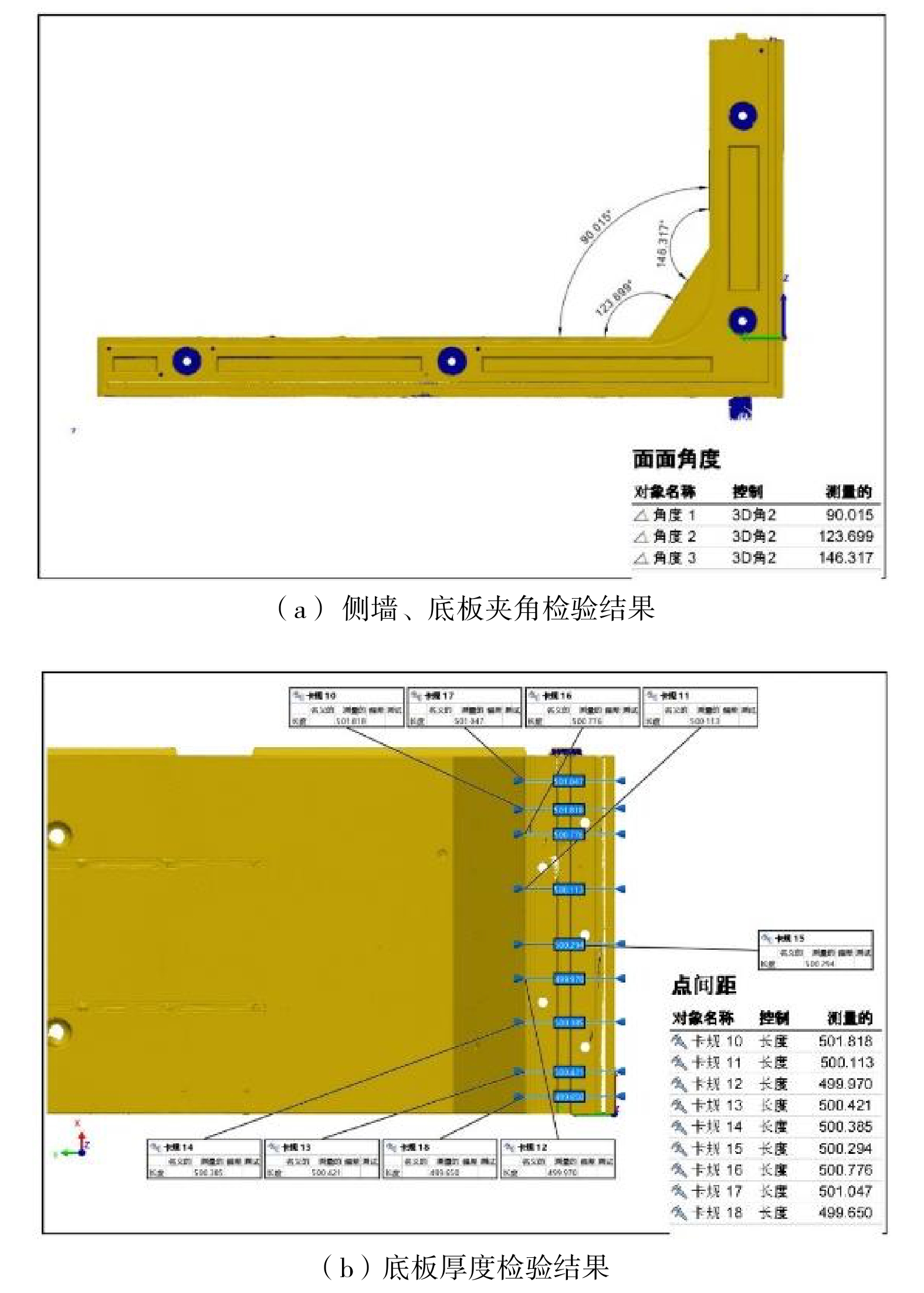

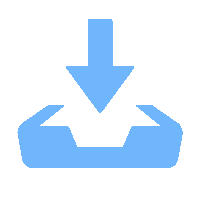

表 1 外观质量检测分析结果

序号 尺寸类型 理论值 最不利

检测值容许差值 实际差值 结果 1 侧墙高度/mm 4610 4607.217 3 2.783 合格 2 节段长(负检测值)/mm 1996 1995.924 1 0.076 合格 3 节段长(正检测值)/mm 1996 1997.535 3 1.535 合格 4 底板厚度/mm 500 501.818 3 1.818 合格 5 侧墙与底板夹角/° 90 90.015 1 0.015 合格 -

[1] 高明昌. 铁路装配式桥梁研究与应用综述[J]. 铁道建筑技术,2023(9):5-9,19. DOI: 10.3969/j.issn.1009-4539.2023.09.002 [2] 张贵忠. 沪通长江大桥BIM技术应用的总结与思考[J]. 中国铁路,2018(11):88-93. DOI: 10.19549/j.issn.1001-683x.2018.11.088. [3] 张 轩,黄新文,李 纯,等. 基于铁路工程的数字化协同设计平台应用研究[J]. 铁道标准设计,2023,67(10):47-54. DOI: 10.13238/j.issn.1004-2954.202306050001. [4] 郭 芳,李达塽,贺晓玲,等. 中国铁路数字工程体系研究[J]. 工程建设标准化,2023(10):76-83. DOI: 10.13924/j.cnki.cecs.2023.10.015. [5] 王焕松,于胜利,卢文龙,等. 基于BIM的企业级铁路施工管理平台研究[J]. 铁道标准设计,2023,67(2):55-59,123. DOI: 10.13238/j.issn.1004-2954.202111020001. [6] 张胜超,靳小飞,赵兴哲,等. 郑州南站装配式联方网壳雨棚智慧建造技术[J]. 智能建筑,2022(3):39-42. [7] 王 永,齐成龙. 基于BIM+GIS技术的预制装配式桥墩全生命周期解决方案[J]. 市政技术,2021,39(4):63-67. DOI: 10.19922/j.1009-7767.2021.04.063. [8] 侯宇飞,杨 斌,吴明杰,等. BIM+GIS数据集成技术在铁路桥梁施工管理的应用[J]. 铁路技术创新,2020(3):29-33. DOI: 10.19550/j.issn.1672-061x.2020.03.029. [9] 王志伟,马伟斌,王子洪,等. 基于轻量化BIM、RFID技术与ERP系统的预制装配式隧道结构智能建造系统[J]. 中国铁路,2020(1):16-21. DOI: 10.19549/j.issn.1001-683x.2020.01.016. [10] 张立宇. 地铁盾构隧道管片流水线生产智能化技术[J]. 现代城市轨道交通,2022(11):47-52.

下载:

下载: